Consumers opting to convert to fully battery electric vehicles (BEVs) expect to see a large lithium-ion battery pack to power the motors. But they might be surprised to also find a conventional 12-volt (12V) battery handling many of the same functions required in cars powered by internal combustion engines.

This somewhat unexpected discovery can be explained by the fact that car manufacturers are grappling with a major design hurdle: the absence of a harmonized, scalable approach for delivering electric power – not only to the motor but to all of the vehicle’s subsystems that 12V has long since supported.

This complexity is compounded by a tremendous increase in power requirements. BEVs need power levels up to 20 times greater than cars with combustion engines. That 20x surge means a corresponding increase in power electronics that adds cost, weight, size and design complexity.

Today’s sub-optimal solution is to pack EVs with as many as three separate batteries – one at 400V or 800V (traction battery), and a distribution system that operates from secondary 12V and 48V batteries.

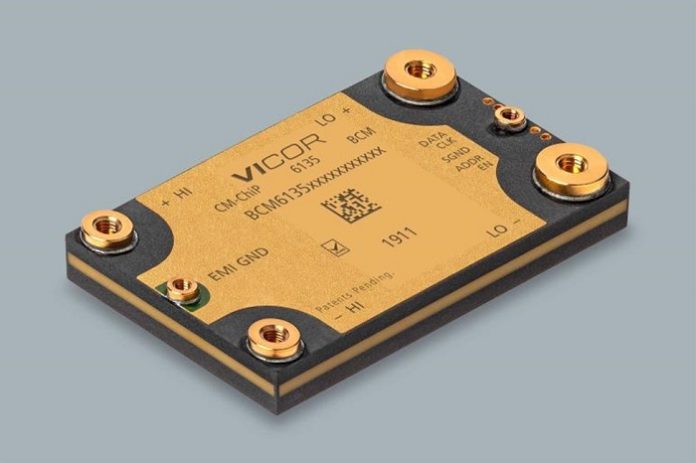

The optimal solution to this design dilemma lies in enabling the traction battery to also serve in the same capacity as the 12V battery. Using solid-state Vicor high-efficiency power module converters in conjunction with Sine Amplitude Converter you can replicate the system demands of the 12V battery—in essence creating a virtual battery.

“Vicor Corporation is working with automotive suppliers and OEMs to eliminate these supplemental power sources by creating a ‘virtual battery’ that responds three times faster than 12V,” said Patrick Kowalyk, Vicor’s Principal Field Applications Engineer. “The solution – a high-performance, modular power converter – converts power from the main 400V or 800V high-voltage battery down to 12V or 48V levels with such a fast response time that a separate battery is no longer needed.”

This replacement strategy not only allows engineers to replicate the essential properties of a physical 12V battery, it enables them to remove more than 25 pounds of vehicle weight and creates enough saved space to fit the equivalent of a small, carry-on suitcase. In 2022, expect to see this modular approach to power delivery being adopted by OEMs that are looking to electrify and differentiate their fleets with extended range and better overall performance.