Explore the Latest Automotive Technologies and Solutions from Shimadzu exclusively at Auto EV India 2022 from 9th to 11th November 2022 at KTPO Bengaluru.

Electronic devices and semiconductor technologies support a variety of industries and add comfort to our lives. Shimadzu develops and manufactures a wide range of instruments to help manufacturers conduct quality control of electronic devices and comply with regulations and directives.

This compilation gives you an insight into the equipment and related applications such as observation of minute parts, elemental analysis, evaluation of optical properties, measurement of hazardous substances, and evaluation of mechanical properties.

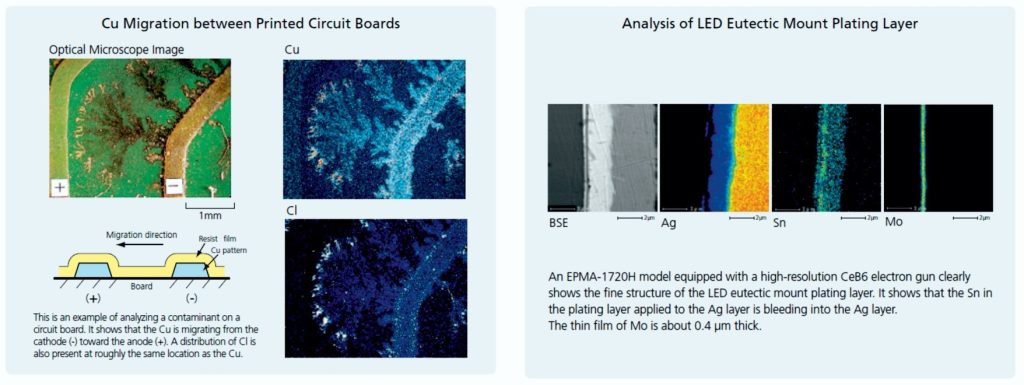

Micro-Area Observation and Elemental Analysis

Submicron Contaminant Analysis and Elemental Analysis of Intermetallic Compounds, Such as Solder Joints for Mounted Devices

Electron Probe Microanalyzer

EPMA-1720 Series

Using only simple mouse operations, EPMA-1720 series microanalyzers can reveal the micron, submicron and even nano-level microstructures in electrical/electronic materials.

micron, submicron and even nano-level microstructures in electrical/electronic materials.

- Enables analysis of submicron-level contaminants or the identity, shape and quantity of

- Non-uniformities and segregations can be determined from element distributions over a large 90×90mm

- Multiple samples can be analyzed successively without human intervention

Elemental Analysis and Chemical State Analysis

Composition/Bond State Analysis of a Sample’s Surface and Metal Surface Discoloration Analysis

Imaging X-Ray Photoelectron Spectrometer

AXIS-Supra Plus

Automated Imaging X-ray Photoelectron Spectrometer

Overview

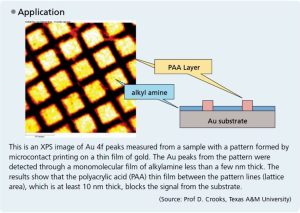

XPS (or ESCA) is a method that measures the bond energy of photoelectrons emitted from solid surfaces irradiated with soft X-rays to analyze the type of elements present in substances and their chemical bond state.

Given that the escape depth of photoelectrons is only a few nanometers, information can only be obtained from layers closest to the surface of solids.

only be obtained from layers closest to the surface of solids.

This method contributes to applications essential for developing nanotechnologies, such as evaluating thin films or multilayer films, controlling contamination of material surfaces and evaluating polymer surface treatments.

Features

Equipped with high-speed XPS imaging functionality based on an imaging-specific analyzer, the system can instantaneously determine the distribution status of elements or chemicals on substance surfaces.

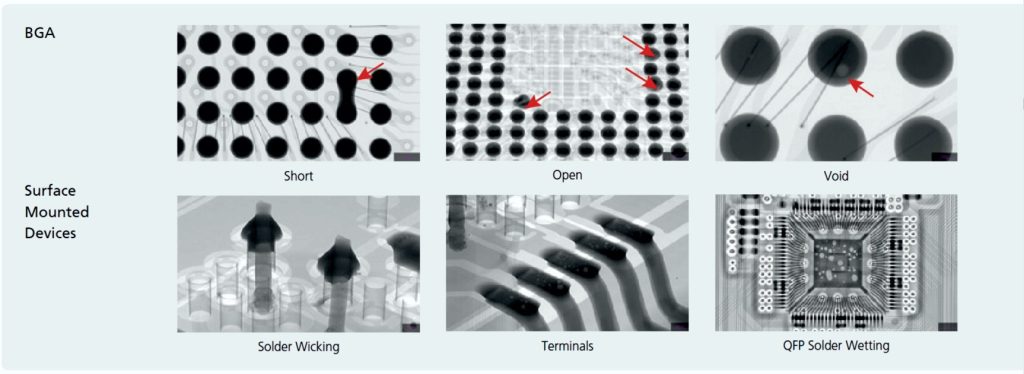

Non-Destructive Observation of Interior Objects

Observation of Internal Structures in Electrical/Electronic Components and Failure Analysis

|

Microfocus X-Ray CT System

Inspection of Solder Joints on Mounted Circuit Boards (BGA Joints, etc.)

Microfocus X-Ray Inspection System

Xslicer SMX-1010 / 1020

- In addition to easier operation, the stage movement and detector acquisition speeds

were increased to significantly shorten inspection times. Consequently, inspection operations can be accomplished more efficiently. Xslicer SMX-1010/1020 systems can be used to inspect a wide range of electrical and electronic components, from surface mounted circuit boards to various sensors and cable harnesses.

were increased to significantly shorten inspection times. Consequently, inspection operations can be accomplished more efficiently. Xslicer SMX-1010/1020 systems can be used to inspect a wide range of electrical and electronic components, from surface mounted circuit boards to various sensors and cable harnesses. - CT functionality is available as an

- A dedicated NDI X-ray pay-as-you-go X-ray generator maintenance service is available for paying only for the X-ray emission time actually used.

Evaluation of Additives and Hazardous Substances

Measurement of Hazardous Substances

Screening for Elements Regulated by RoHS/ELV Directives

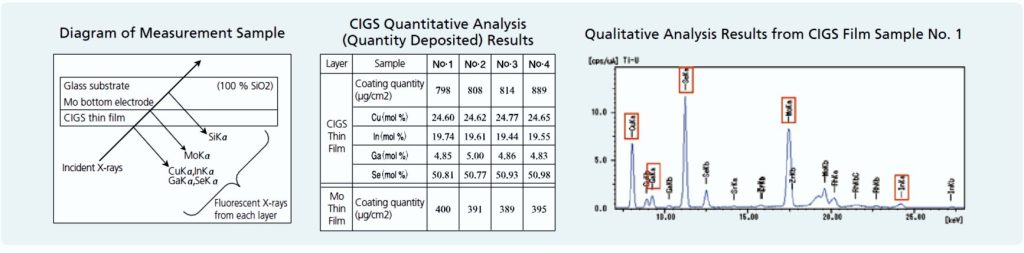

Analysis of Elements in Layer Structure and Elemental Analysis of Contaminants

Energy Dispersive X-Ray Fluorescence Spectrometer

EDX-7200 / 8100

Compound-type solar cells are made by depositing a thin film of a compound on a substrate by sputtering or another method. Energy dispersive X-ray Fluorescence spectrometers provide a very convenient means of quickly and non-destructively measuring CIGS thin films.

substrate by sputtering or another method. Energy dispersive X-ray Fluorescence spectrometers provide a very convenient means of quickly and non-destructively measuring CIGS thin films.

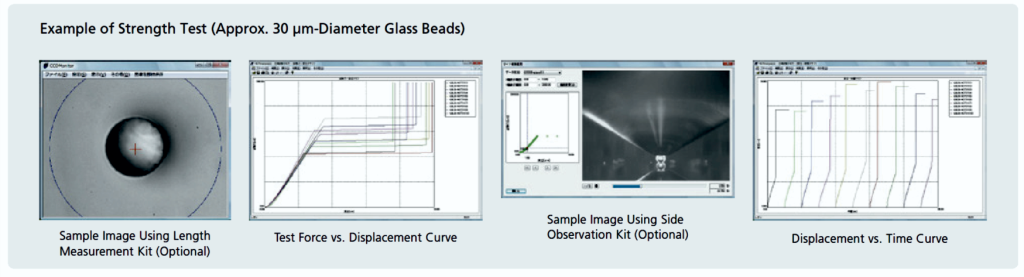

Evaluation of Strength

Various Strength Evaluations of Electronic Components, Circuit Boards, etc. (Peeling Test, Shearing Test, etc.)

Precision Universal Testing Machine

AGX-V Series

These motor-actuated precision universal testing machines provide high performance, easy operability, and safety. In addition to a wider range of speeds, higher rigidity, a load cell that increases the guaranteed measurement precision range to 1/2000, and other basic performance improvements, these models also feature a newly designed controller that supports even more complex testing methods. Furthermore, the crosshead position is remembered even when the power is switched OFF to make setting the grip space easier and built-in functionality prevents instrument collisions. The software includes additional functionality without sacrificing ease of operation.

operability, and safety. In addition to a wider range of speeds, higher rigidity, a load cell that increases the guaranteed measurement precision range to 1/2000, and other basic performance improvements, these models also feature a newly designed controller that supports even more complex testing methods. Furthermore, the crosshead position is remembered even when the power is switched OFF to make setting the grip space easier and built-in functionality prevents instrument collisions. The software includes additional functionality without sacrificing ease of operation.

- Evaluate the solder joint strength of electronic components soldered to printed circuit

- Measure the tensile strength of resist and insulator films on printed circuit

- Evaluate the force required to connect/disconnect connector

- Perform solder joint peeling

|

Compact Tabletop Testing Machine