The TSB582 is ST’s first high-voltage and high-current dual-operational amplifier with one of the smallest packages in the industry (SO8 with exposed pad and DFN8 with wettable flanks and exposed pad). Our teams first considered it for resolvers in electric vehicles or other applications with high-powered AC or BLDC motor applications that must translate mechanical movement into electrical data to determine the motor’s position and improve efficiency. Moreover, its size and pin-to-pin compatibility with our other op-amps makes it a tremendous general-purpose device for piezo actuators, among other things. Consequently, we featured the TSB582 at Embedded World 2023 and the latest Toronto Technology Tour in a driving simulation demo.

Why are resolvers important in EVs?

Precision in motor control algorithms

Electric vehicles must carefully adjust the current sent to each of their motors to provide optimal performance. For instance, when an EV turns left, the motor control algorithm must quickly and accurately drive the IGBTs on the right and left motors to create the proper torque to ensure a smooth driving experience. Similarly, pushing the gas pedal must be met with immediate acceleration, and knowing the wheel’s exact position will ensure the driver can easily control the automobile. Put simply, the wheel’s exact position is crucial for the motor control algorithm. The question then becomes why engineers would use a resolver rather than an encoder.

The resolver uses a primary coil in a rotor. Besides this reference coil, there are two secondary windings, in a stator, placed at 90º from each other. One is called the sine winding because the system reports its sine amplitude, while the other is the cosine winding. Put simply, an alternating current passes through the primary coil, and as it moves, its electromagnetic field excites the secondary windings. By measuring current changes at each winding, it is possible to obtain sine and cosine functions. Afterwards, a program can get the precise angle of the rotor by applying an inverse tangent function using the sine and cosine values.

Resolvers and the democratization of EVs

A glance at this basic overview of the inside of a resolver shows that this sensor is fast and robust since there are no intricate mechanisms or complex electronics that could fail. It also explains why makers choose to use resolvers instead of encoders. A resolver can tolerate high temperatures, and car makers can place them closer to the motor without worrying about operating conditions. It also shows why manufacturers are constantly looking to shrink resolvers. By using a smaller design and fewer components, teams can create something more robust and easier to use. Hence, any improvement that further increases the attractiveness of a resolver will also help bring costs down and make EVs more accessible.

Why is the TSB582 popular in resolvers?

Optimization of the bill of materials

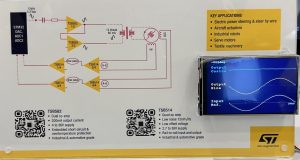

Given the workings of a resolver, it’s easy to understand why engineers traditionally use two operational amplifiers with the primary coil. However, by providing two channels, the TSB582 allows designers to use only one high-current op-amp, thus cutting the power stage by half and lowering the bill of materials. Additionally, it is possible to use the two channels in parallel to double the output current to 400 mA, which will fit in industrial applications that use servo motors or robot arms, for instance. Furthermore, its pin-to-pin compatibility with other operational amplifiers means teams get a more practical device. They can qualify it once and use it in multiple designs, thus reducing costs.

Protections against harsher conditions

Another essential benefit of resolvers is their ruggedness. Consequently, the TSB582 comes with an output current limiter as well as short-circuit and over-temperature protections to help deal with even harsher conditions. For example, in the case of the thermal safety feature, the device automatically turns off the output power stage to allow it to cool down, and it restarts once the temperature drops below a certain level. Engineers don’t have to worry about adding those safeguards but can take advantage of them as they plan for extreme conditions. The ST data sheet even includes PCB layout recommendations and application examples to help designers get started.