Authors: Akshat JAIN, STMicroelectronics India, Fabrizio Di FRANCO, STMicroelectronics, Italy, Martin DENDA, Rene WUTTE, STMicroelectronics Austria, Bruno TISSERAND, STMicroelectronics, France

Wireless power is going to introduce significant innovations in kitchens, making them smarter, sleeker and more space-efficient. Appliances from simple low-power juicers to blenders or kettles, and others that require up to 2.2 kW of power will benefit by eliminating power cords thanks to the new standard “Ki Cordless Kitchen” that is set to be released by the Wireless Power Consortium. The key driver of rapid adoption is interoperability. All certified Ki transmitters and appliances will follow defined safety protocols and work with each other, regardless of the brand, device type, or version of Ki they use.

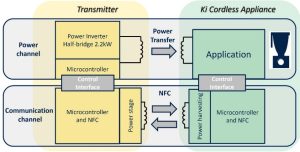

The Ki transmitter can also be considered a smart induction cooktop that will not only power Ki receivers but also operate standard induction utensils like heating a pan. Ki enables smart communication between transmitters and appliances based on Near Field Communication (NFC) providing auxiliary power, bi-directional data paths, advanced control features, authentication and protections (FOD) and it is essential for interoperability. The block diagram of the Ki Cordless Kitchen concept block diagram is highlighted in Figure 1.

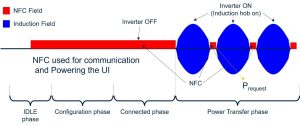

To prevent interference between NFC and wireless induction power transfer during the power transfer state, the wireless induction power transfer is switched completely off during the mains crossing and NFC becomes active as shown in Figure 4.

Ki receiver vs Induction Utensil (Pan/Pot)

The standard induction utensils are made of ferromagnetic materials. The bottom of an induction utensil (pan/pot) can be treated as an induction coil with one winding and low load resistance where received power is dissipated. So, the power transmitter coil and utensil can be considered a transformer in which the induction utensil acts as a shorted secondary (load). An alternating current is made to flow through the transmitter resonant power coil, which leads to the generation of an oscillating magnetic field. The magnetic field induces an electric current inside the induction utensil.

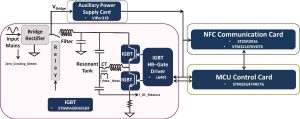

The Ki receiver mainly consists of a resonant power coil, resonant capacitor, NFC circuitry and Ki receiver/appliance circuitry. For the Ki transmitter the power coil is fixed but for the Ki receivers, the size of the power coil varies depending on the power requirements. To maximize the energy transfer, the Ki receiver must be tuned to the transmitter’s resonant frequency. Now, there will be two resonance points: one of the Ki transmitter and the other of the Ki receiver. To have better efficiency, the transmitter needs to operate at a second resonant frequency, but that doesn’t guarantee the maximum power required by the Ki receiver. To transmit the desired power the Ki transmitter needs to shift to the first resonant frequency. The resonant shift is managed by the STM32G474RET6 microcontroller control algorithm.

To shorten the development time and let customers evaluate products in the final application, STMicroelectronics offers a reference design (STEVAL-KITXCB) for the transmitter and is working on the reference design for the different types of receivers. The hardware design files and firmware source code are available with developer-friendly license terms. For more details, please contact the STMicroelectronics sales office.