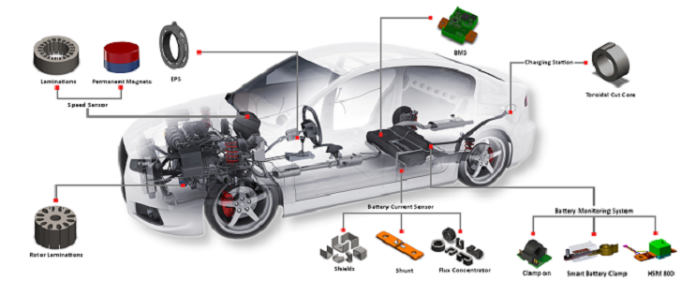

Explore the Latest Automotive Technologies and Solutions from Permanent Magnets Ltd. exclusively at Auto EV India 2022 from 9th to 11th November 2022 at KTPO Bengaluru.

Permanent Magnets Limited is among the flagship companies of Taparia Group, Mumbai, and a front-runner among young, lively, and growing companies. PML magnets are utilized extensively in key business sectors like electronics, power meters, automobile industries, telecommunication, defense, space research, aeronautics, rail transport, and power generation.

Following are the products that will be displayed by them at the Auto EV India 2022-

Battery Current Sensor:

- Shields

The laminated U-shield is a soft ferromagnetic shield featuring superior material characteristics such as high linearity and very low hysteresis. It is available with two different materials: Ni-Fe and Si-Fe.

The shield is designed for planar current sensing in combination with a magnetic field sensor, i.e., a Hall sensor, an AMR sensor, and a busbar conductor. The LU shield protects the sensor from parasitic magnetic fields caused by nearby conductors or other magnetic field sources while at the same time it enhances the sensitivity and the signal-to-offset ratio of the sensor.

Thanks to its laminated design it is suitable for high-speed applications.

- Shunts

The shunt is designed for precision current measurement with high thermal stability in instruments, industrial, and automotive applications, typically including energy meters, ampere meters, power inverters, and battery current monitoring.

- Flux concentrator/C-core

Flux concentrators are made up of thin strips of soft magnetic materials (High permeability, low remanence and low eddy current losses). When surrounded to current-carrying conductors it increases the flux density. As the effective permeability of the material is high, it amplifies the flux density. At the same time, the gap or air gap of the flux concentrator aids in positioning the hall effect sensor at an appropriate distance from the conductor. The distance between the sensor and the conductor determines the accuracy of measurement.

Factors like the type of current measurement (either low or high), Frequency, Atmospheric conditions, and end application determine the specific material grade to be used.

The C-Core is a laminated soft ferromagnetic core featuring superior material characteristics such as high linearity and very low hysteresis. It is available with two different materials: Ni- Fe and Si-Fe. The core is designed for high-speed contactless current sensing in combination with a magnetic field sensor, i.e., a Hall sensor, and a current conductor. Furthermore, the core protects the sensor from parasitic magnetic fields caused by nearby conductors or other magnetic field sources.

Battery Monitoring System:

- Clamp on

- Smart Battery system

- HSM 800

A Battery Management System (BMS), which manages the electronics of a rechargeable battery, whether a cell or a battery pack, thus becomes a crucial factor in ensuring electric vehicle safety. It safeguards both the user and the battery by ensuring that the cell operates within its safe operating parameters.

The BMS monitors parameters such as temperature, input and output current, and voltage across the battery packs to ensure the safe operation of the battery.

The “clamp-on” current sensors are particularly useful for easy and safe installation. They are installed straightforwardly onto a wire going into the electrical load without the need to do any high-voltage electrical work. The current sensor consists of a Melexis Hall Sensor (MLX91208) and a patented ferromagnetic structure packaged in robust plastic housing.

This non-invasive current sensor (also known as a “split core” or “cable-clamp”) can be clamped around the supply line of any electrical load to tell you how much current is passing through it. It monitors the magnetic field around a current-carrying conductor and outputs a voltage proportional to the current.

The clamp-on current sensors measure loads from +/-5 Amps to +/-230 Amps which makes it great for building your own energy monitor to keep your power usage down, or even building an over-current protection device for an AC load.

Speed Sensor

- Laminations

- Permanent magnets

PML is supplying components and systems for current measurement, battery management, motors/generators, charging systems, torque and angle measurement systems, safety and automation.

PML has developed modules and assemblies for various applications such as intelligent battery sensors, and battery monitoring systems.

Rotor Laminations

Motors/Generators/Alternators are typically used to convert one form of energy into another. Stators and Rotors are the key factors in these appliances. Stator and Rotor decide the efficiency, accuracy, construction etc. Hence it is very crucial to select appropriate material as per specified needs. Cobalt Iron, Nickel Steel, and Silicon Steel are the typically used materials.

Thin laminations made using these materials are used in the stator and rotor of the motors/generators/alternators. Soft magnetic laminations have high magnetic permeability and thin sections, lower the eddy current losses. Various coatings such as Oxidation, Epoxy, Electro deposition (ED), Electrophoretic (EP) etc., help in maintaining electrical insulation. These coatings also allow magnetic conductivity, which helps in maintaining the eddy current losses and heat to the minimum. Hence the overall efficiency of the motor/generator/alternator is elevated.

EPS

Power steering uses the motor to assist you in steering the vehicle. If the engine is off or if the power steering system becomes inoperative, the vehicle may still be steered, but it will require increased steering effort.

Energy Meter CT’s

A current transformer (CT) is used for the measurement of alternating electric current for energy meter. Current transformers, together with voltage (or potential) transformers (VT or PT), are known as instrument transformers. When the current in a circuit is too high to apply directly to measuring instruments, a current transformer produces a reduced current accurately proportional to the current in the circuit, which can be conveniently connected to measuring and recording instruments.

A current transformer isolates the measuring instruments from what may be very high voltage in the monitored circuit. Current transformers are commonly used in metering and protective relays in the electrical power industry.

EV charger

Electric vehicle charging guns are mainly used to charge electric vehicles. The charging gun acts as an interface between the charging device and the rechargeable battery of the electric vehicle.

Salient Features:

3 phase/single phase, 16A/32A, type-2 connector as per IEC 69196-2. Power rating: 7.2/11/22 kW.

Over-molded design for better performance and quality standards.

Operating temperature range: -30°C ~ +50°C.

Inverter Assembly

An inverter is a device that converts DC power to the AC power used in an electric vehicle motor. The inverter can change the speed at which the motor rotates by adjusting the frequency of the alternating current.

AC Phase assembly (On Board charger):

It is also called the “onboard charger” though it really is a converter. It converts power from AC to DC and then feeds it into the car’s battery. This is the most common charging method for electric vehicles today and most chargers use AC power.

Courtesy: Permanent Magnets Ltd.