The evolving future of vehicular electrification is notably dependent on the availability of stable and unfailing sensors.

While people think that electric vehicles only sprung up in the last decade, their history is actually long and complicated. Introduced in the 19th century, they failed to make lasting impressions. In the last decade, fitful efforts have been made to revive EVs. The inconvenience of an electric vehicle, with time, is cornering to minimal. Electric vehicles are on the rise. Sales of electric vehicles are spurred by a list of incentives designed to encourage adoption.

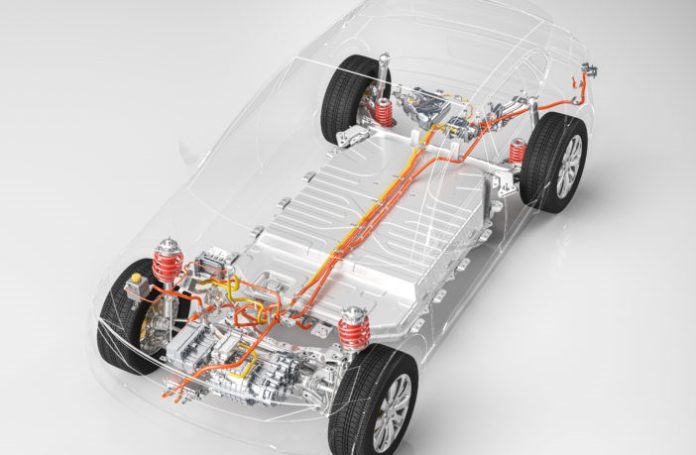

Technologies powering EVs are evolving and are working towards making significant changes in the power system and environment. Electric vehicle sensors for batteries are more than an updated version of a gas gauge. They are refined tools for measuring the key performance in vehicles. Electric vehicles have different subsystems and they coordinate among themselves to make an EV work. The battery in an electric vehicle acts as a generator and not a propulsion unit which reduces the number of sensors required. The number of gears needed for transmission gets reduced by a large number and as a result, the number of position sensors needed is only one or two. The exhaust sensors to measure pressure, temperature and oxygen are no longer required. Sensors in EVs are used to measure the battery health, update about the humidity control, thermal management and energy management, voltage management, and the flow of control.

Position Sensors

Angle position sensors are mostly used during the transformation of angular mechanical motion data into an electrical signal accurately. Encoder and resolver are the two mainly used. resolver is an analog position sensor and looks like a small transformer. The sensing mechanism is done by calculating the effective turn ratio and polarity between the two sets of coils. Encoders are used as motor position sensors. The three most used encoders are incremental, incremental sinusoidal signal, and absolute position value.

Battery Monitoring Sensors

They are attached above lead acid batteries for health monitoring. The health monitoring and state of charge of the battery become important for systems and motors operating at a higher voltage. The three main measurements of the sensor in this regard are voltage, temperature, and current. Voltage measurements among them are most critical, as batteries consist of a group of cells, with each cell attached with a voltage measurement chip. For current measurements, shunt resistors or open-loop hall sensors are generally used. For temperature measurements, NTC thermistors are generally used.

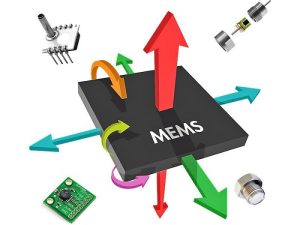

MEMS Sensors

A Micro electro-mechanical system is a chip-based technology where sensors are composed of a suspended mass between a pair of capacitive plates. When the sensor is tilted, a difference in electrical potential is created by this suspended mass. The created difference is then measured as a change in capacitance. The most commonly used are airbags and vehicle stability control. MEMS technologies are classified into four divisions- accelerometers, gyroscopes, inclinometers, and flow and pressure sensors. The technology has been welcomed as it has significant benefits like low cost, reliability, and increased performance from other microscopic electromechanical sensors.

Thermal Management

Excessive heat is one of the most detrimental environments for an EV’s battery. If left unchecked, thermal runaway can cause a battery cell to degrade and release flammable gases. It can trigger a chain reaction through the battery pack which damages it beyond repair. Battery cells can degrade quickly at higher temperatures, which requires that the system be controlled by heat exchangers that can both extract heat from the cells or add heat as needed, and all require accurate temperature sensor feedback.

Humidity Control

The biggest enemy of an EV battery’s design is humidity. Monitoring the battery pack for condensation buildup over long life spans has become more of a concern. Water from humidity in the form of condensate and the potential for small leaks in the pack’s cooling system can lead to electrical shorts and corrosion, which can damage the pack and form dangerous levels of hydrogen gas.

Energy Management

Electric vehicles, of any size and shape, require a lot of energy. So, monitoring its energy intake during charging and consumption during utilization is vital for consistent performance. Consumers look foremostly for the feature of fast charging which requires monitoring as overcharging can cause damage.

Battery Health

For many potential adopters, EV battery performance is thought to be a barrier. Nobody wants to be stranded in the middle of the road because of a failed battery performance without a proper warning. The owner needs to know how far the vehicle can go on the current charge, to stop small performance issues before they become bigger, and assess the usefulness over the long term.

Current leaders in the Sensor market

Analog devices, NXP Semiconductors, Infineon Technologies AG, Texas instruments incorporated, Denso, Vishay Intertechnology Inc, and STMicroelectronics are some of the leading players in the global electric vehicles sensor markets. India’s automotive sensors market is dominated by names such as Continental AG, Aptiv, Robert Bosch, and Hyundai Mobis.

Sensors play a critical role in supplying accurate measurements of State-of-Health and State-of-Charge. The electric vehicle industry is in the starting stages of unprecedented growth, and sensor technology is set to follow suit. Government regulations play a significant role in the growth of the market for sensors, used especially in automotive applications. Although there is still some consumer reluctance to accept the latest evolution in transportation, today’s electric vehicle sensors can ensure a bus, car or even a plane ride is of much higher quality.